I advise on automation technology, digitalisation, machine learning and sensor and measurement technology in water treatment.

I plan measurement and control technology for water treatment systems and other process plants, condition monitoring and environmental monitoring systems and their analysis tools.

I program, administer and configure PLCs (Siemens S7, WAGO, B&R and other IEC 61131-based systems), IIoT applications, remote maintenance systems and remote control.

Your advantage,

Do you want to implement an idea in the area of industrial IoT, digitalisation or automation in your company - but you lack expertise? Get in touch and we'll develop a concept together.

My Goal.

With my work, clients are empowered to follow a sustainable path of digitalisation. They have the opportunity to use information and communication technology for a climate protection-oriented future of their products and services. In this way, they actively move towards the necessary paradigm shift. A fundamental building block of my work should be the sensible use of digital technology for a regulated and measurable emissions turnaround. Let's use technology properly.

Products

Projects

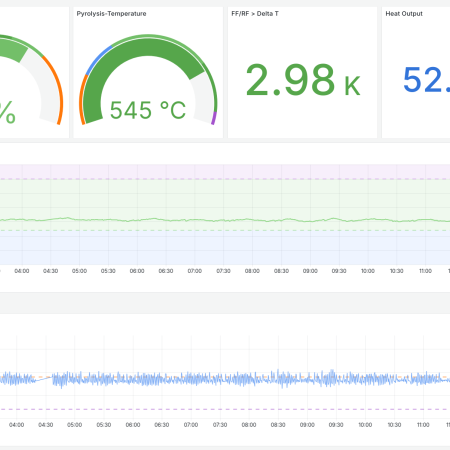

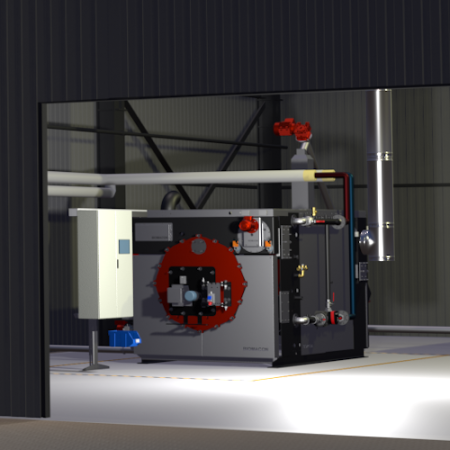

Monitoring Pyrolysis Boilers

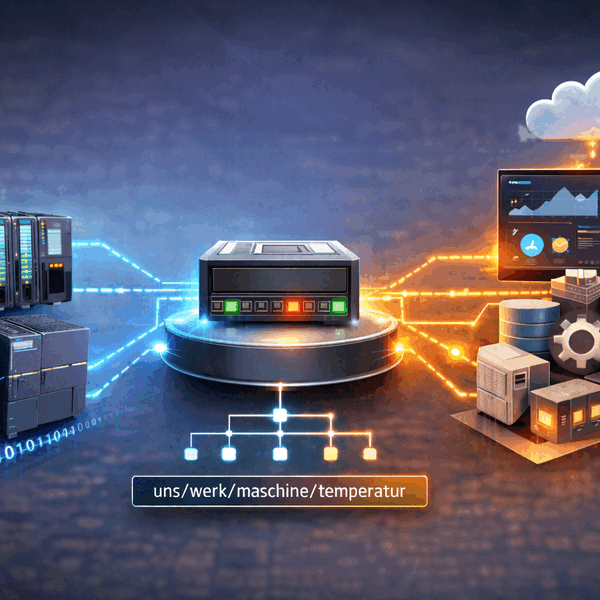

Pyrolysis boilers burn biomass highly efficiently – when they run optimally. However, without continuous monitoring, inefficiencies remain invisible: Too low combustion temperatures lead to energy losses, suboptimal oxygen supply results in incomplete combustion. This monitoring system captures over 300 data points per minute from Siemens S7 controllers and transmits them via MQTT and SparkplugB into a Unified Namespace. InfluxDB stores the time-series data, while Grafana dashboards provide real-time visualization and alerting. The result: Transparent operations management, optimized combustion, and centralized administration of multiple facilities across locations.

Technologies Used:

- Siemens S7 PLC

- MQTT & SparkplugB

- InfluxDB & Grafana

- Unified Namespace Architecture

- NodeRED

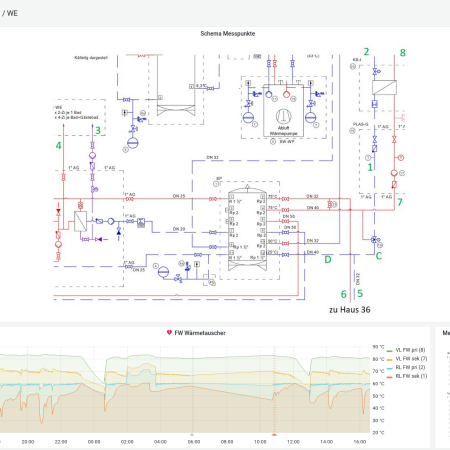

4E Engineers Technical Monitoring

Together with the company 4E Engineers, a FOSS-architecture was designed and set up to allow for the comprehensive monitoring of any components of a building's technical equipment. Highly flexible edge node gateways collect data from a wide range of protocols, which are then made available for further analysis.

Technologies used:

- Docker

- Grafana

- InfluxDB

- NodeRED

- Flux

- Modbus

- 1-Wire

- WMBus

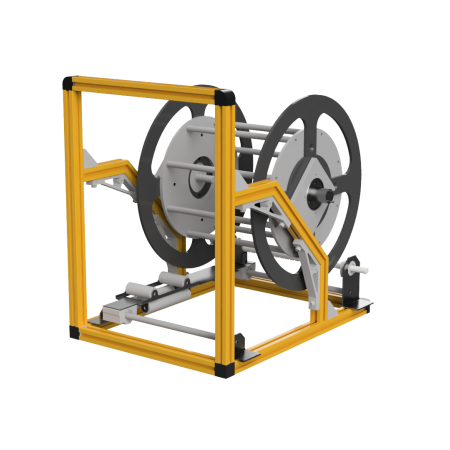

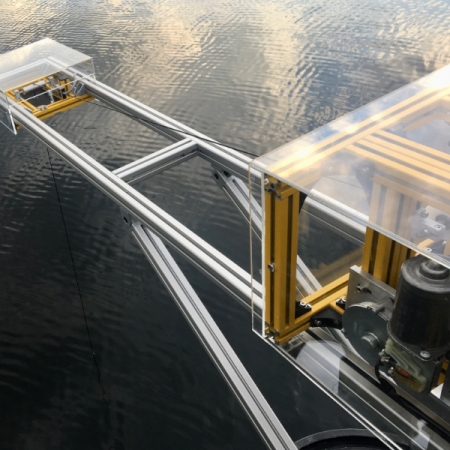

MEDIRA Monitoring Profiler

The next generation for automated depth profile monitoring. Compared to previous developments, the cable is spooled onto the drum with this winch. A cross-thread spindle acts as a linear guide to ensure the cable is placed on the drum in an orderly manner. The overall system is much more compact and versatile.

Technologies used:

- Own construction of the winch technology

- Rotating signal transmission

- Cross-thread spindle

Technical animations BIOMACON

For the transfer of knowledge and technology, technical animations of the structure of their pyrolysis systems were created for BIOMACON GmbH. The aim was to schematically convey the structure of a pyrolysis system. This was realised based on 3D models of the plant and specially created objects. The resulting scenes were animated and then rendered as video sequences. These serve as visual instructions for the construction of a BIOMACON plant in India.

Technologies used:

- Blender 2.9

- FreeCAD 0.19

- Animation Nodes

OMIO - onlinemonitoring.io

With OMIO I provide a service for secure, fast and easy management of your real-time data. Open source tools are orchestrated for data acquisition, storage and analysis to provide a basis for further analysis tools and algorithms. In addition, an interface for the connection of water monitoring winches has been developed.

Technologies used:

- MQTT

- NodeRED

- Telegraf

- InfluxDB

- Grafana

- Python

- GRAV CMS

- Docker Container

Automated Water Monitoring

Water monitoring in reservoirs requires continuous depth profiles – previously only possible manually from boats. This profiler winch fully automates the process: Up to 8 times daily, an OTT HydroLab 7 probe captures oxygen, temperature, pH value, and algae concentration across the entire water column. The measurement data flows directly into the central control system of the Aabach reservoir, which supplies drinking water to 200,000 residents. The result: Comprehensive data monitoring for optimal operation of the deep-water aeration system – without manual boat trips.

Technologies Used:

- Siemens S7-1200 PLC

- OTT HydroLab 7 multiparameter probe

- OTT netDL 1000 data logger

- Unigate MB protocol converter

- Custom winch design (100m cable capacity)

About

Tobias Ehn

Dipl. Wi.-Eng.

Focus Areas:

- Product and Production Development

- Project and Innovation Management

Professional Experience:

6 years as Project Engineer in Energy and Environmental Technology.

- hydraulic design, electrical planning and automation of ecological water treatment plants

- database development

7 years self-employed - Engineering Office for Sustainable Digitalization.

- PLC programming

- Planning and implementation of water monitoring systems

- Planning, design and project support for pyrolysis heating systems

- Planning of water treatment plants

- Automation of pumping stations

- Automation of wastewater pumping stations

- IT concepts in automation technology

- Process data acquisition and analysis

- CAD development and 3D computer graphics

Email: info@te-c.net